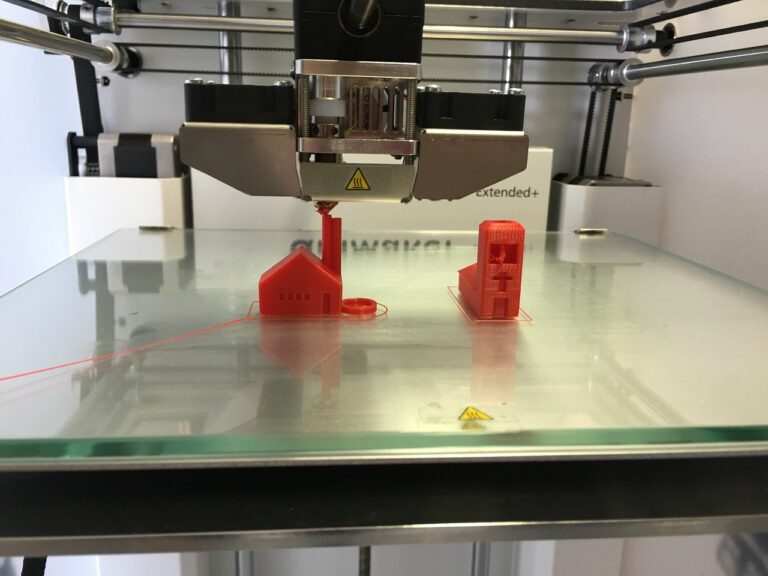

The delivery of 3D printing technology is way more than a human grip. Can you imagine it can wrap up a 600 to 800-square-foot in just 24 hours? And, of course, it has other areas to deliver the benefits. It has come a long way in recent years, and its potential to help save the environment is also massive.

3D printing presents us with an exceptional opportunity to reduce waste and create a greener, more efficient use of materials. Moreover, it has a far smaller carbon footprint than traditional manufacturing processes. It uses significantly less energy and produces fewer emissions, while still providing the same level of quality and functionality.

Table of Contents

5 major environmental benefits of using 3D printing technology

This technology is a very impactful and revolutionary step towards reducing wastage. Here are five ways that 3D printing can help save the environment.

1. Lessen the raw material uses

3D printing can use less raw material than traditional manufacturing processes. For example, in injection molding, much of the material goes to waste because it is used to coat the mold.

With 3D printing, the material is only used where it is needed. This may result in a large decrease in the quantity of garbage waste produced.

2. Reduce inventory

3D printing can help reduce the need for inventory. Traditional manufacturing processes require that companies keep a large stock of parts on hand in case something breaks. With this technology, companies can print parts as needed.

This can lead to a reduction in the amount of money spent on inventory and a reduction in the amount of storage space required.

3. More secluded, compact factories

3D printing can allow for more secluded and compact factories. Because 3D printers can print parts as needed, there is no need for large assembly lines. This can lead to a reduction in the amount of space required for manufacturing.

By downsizing traditional factories into more compact manufacturing centers, companies can reduce their environmental footprint by decreasing the amount of energy used and resources needed to produce products. This can also lead to a decrease in emissions, as these more confined factories can more effectively capture and reuse their byproducts.

4. Streamline production

3D printing can also help streamline the production process by eliminating the need for manual assembly. Instead of having individual components that must be manually put together, 3D printing allows companies to produce a single, fully integrated piece that is ready for use right out of the printer.

By reducing the number of steps involved in the production process, it can help reduce the time and materials required to make a thing.

This can ultimately lead to a decrease in emissions and energy use, as well as fewer resources wasted. In traditional manufacturing, parts have to be designed for the manufacturing process. With 3D printing, parts can be designed for end users. This can lead to a reduction in the time and money required to produce a product.

5. Spare parts and repairability

3D printing can be used to create spare parts and repair products. Another way of using 3D printing, and building a more sustainable future is by enabling the production of spare parts and repair products. With traditional manufacturing methods, companies produced large runs of certain parts to keep prices low.

However, this often resulted in an abundance of spare parts that were never used. Then again, this technology enables businesses to manufacture only the pieces required for a particular task. This helps reduce waste and improves the speed and efficiency of repairs. This can extend a product’s life, reducing the need for frequent replacements and helping to create a more circular economy.

The potential of 3D printing for the circular economy

Imagine a future where everything you need is made using 3D printing. Your clothes, furniture, and even your food are all created using this innovative technology. Not only would this be more convenient, but it would also be much better for the environment. That’s because 3D printing has the potential to reduce waste in the manufacturing process drastically. Instead of cutting and shaping materials to fit a particular design, it allows products to be created using only the necessary amount.

This could have a huge impact on the circular economy, which is based on reducing waste and ensuring that resources are used efficiently. In a world where it is commonplace, recycling materials and creating products that last longer would be easier. As a result, we would be able to close the loop on manufacturing, creating a more sustainable future for generations to come.

How is 3D printing the technology of the future?

Today, 3D printing technology is used to create everything from prosthetic body parts to eyeglasses to entire houses. In the future, this technology will only become more widespread and more sophisticated. As 3D printers become more advanced, they can create increasingly complex products. Eventually, it may even be possible to print out working electronics.

This would revolutionize the manufacturing industry, as products could be produced on demand with very little waste.

Moreover, 3D printing could also be used to create customized products. Instead of mass-producing the same item repeatedly, companies would be able to produce unique items specifically tailored to each customer’s needs. In many ways, it is the technology of the future.

Read also: 7 best innovations to tackle climate change