The excitement surrounding 3D printing has captivated mainstream media readers for years. This fact results from 3D printers now being accessible as everyday objects.

Interestingly, people are naturally intrigued by the capacity to conjure up actual three-dimensional objects “out of thin air,” and for a good reason.

Table of Contents

How does a 3D printer work

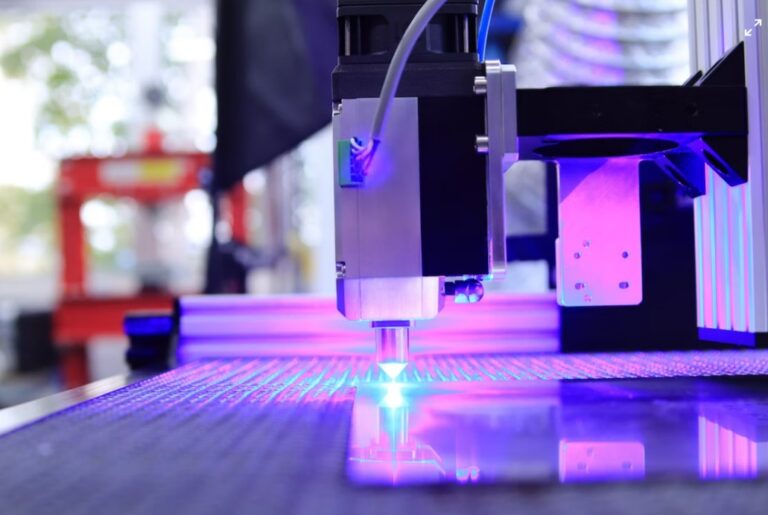

3D printing, referred to as “additive manufacturing” operates by building up a 3D object from a digital file layer by layer.

As a result, each of the tiny layers would be visible if you cut open a final 3D-printed object, much like the rings in a tree trunk. In the manufacturing and automotive industries, 3D printers are frequently utilized to create tools and parts.

The value of 3D printing increases along with its capabilities, but specifically, what can be produced using a 3D printer?

The technology used by 3D printers is similar to those of conventional printers. Fused deposition modelling (FDM), also referred to as fused filament fabrication (FFF), is the most well-known. It involves melting and layering the deposition of a filament made of polylactic acid (PLA), ABS, or another thermoplastic through a heated extrusion nozzle.

What can you make with a 3D printer?

Modern technology like 3D printing has uses in both the corporate and leisure worlds.

Here are some examples of items you can create using a 3D printer:

Functional components

A metal mould typically shapes the material and creates most plastic components. It is quick and simple to repeat the process. However, making the moulds requires time. Only after producing a large number of goods does production become cost-effective.

Small batch production is made possible by 3D printing, providing greater flexibility and control. In addition, 3D printing allows for quick production line replacement parts. Costly downtimes are thereby minimized.

Conceptual models

The computer design of a structure can benefit significantly from a 3D-printed architectural model. Before surgery, medical models help explain procedures to patients and plan them for the specific instance.

The most common use of 3D printing is rapid prototyping. In a few hours, digital designs can become tangible objects.

Prototypes

By creating numerous 3D-printed prototypes, product designers can evaluate and refine their ideas. Engineers can conduct multiple tests by developing numerous test goods (heat resistance, impact, strength, etc.).

Jewellery

The world of jewellery-making also benefits from 3D printing technologies. Jewellery creators can experiment with different designs, which isn’t possible with other traditional methods.

Creating jewellery with a 3D printer allows for designing unique custom-made pieces at a lower cost.

Buildings

A simple house can be 3D printed by the Russian business Apis Cor in just 24 hours, saving up to 40% on building expenses.

After the walls are constructed using layers of a concrete mixture laid down by the mobile printer, insulation, windows, and a roof is added. Additionally, since Apis Cor’s portable printing equipment, printing homes can be done on-site rather than in a factory.

Read also: Top 5 innovative housing projects made with a 3D printer

Bringing cities To life using 3D printer

Architecture stands to gain much from developments in 3D printing technology since it is a field that is already built on geometric design, prototyping, and modelling.

In addition to speeding up the model-making process, 3D-printed models let architects predict the effects of particular design elements with much more assurance. For instance, by viewing a model made with a fuller complement of materials, an architect can measure aspects like light flow through the structure with greater accuracy.

End-use parts for high-performance footwear

The sports footwear market has traditionally relied on technology to improve the performance of its goods, and the advent of the digital workflow has given them more customization options than before.

Large companies like New Balance, Adidas, and Nike plan to build unique midsoles in large quantities using 3D printed materials. after realizing the potential of additive manufacturing.

Like other industries, the digital workflow will supplement traditional ways of production in this one. Each product’s key, highly personalized components will be entrusted to 3D printing, while the remainder will be produced using conventional methods.

Read also: From mass production to mass customization: the future of manufacturing