The technology using 3D printer has created a ton of amazing constructions during the past five years around the world. The construction of houses, cabins, offices, bridges, pavilions, huge structures, shelters, and more has been in high demand.

On the other hand, building materials have undergone a lot more change over time. New building materials have left their imprint throughout history and throughout civilizations making huge possibilities emerge. As a result of this transformation, the use of hay, tree barks, stone, lumber, brick, mortar, glass, and steel have gone extinct. The traditional construction method has been disrupted as 3D construction gains popularity.

Table of Contents

The traditional evolution of 3d printer

Materials have a significant impact on how a space feels to be in. Different materials began to be used in 3D printers during this phase. This technology can now be used to print dwellings in three dimensions.

Various materials offer varying degrees of thermal and acoustic comfort. Additionally, materials differ according to location and unique environmental circumstances. This reinforces the idea that “Change is the only constant” due to differences in building materials.

For instance, just the brick has gone through several evolutions. Fly ash bricks, hollow wooden bricks, etc. have evolved from clay and sand bricks. The variety of materials is therefore very broad.

Additionally, technical advancements have produced unusual methods and materials. This not only lessens the building’s negative environmental impact but also lengthens its lifespan and strengthens it. The use of materials like bamboo, wood, recyclable waste, bitumen materials, tempered glass, crumb rubber, etc. is one example of this.

New-age materials like Fiber Reinforced Polymer, Glass Fiber Reinforced Plastics, Bamboo Reinforced Plastics, etc. are also included in this list. The newest and most amazing breakthrough of our day, however, is 3D printed housing.

The advantage of 3D printed homes isn’t just in their speed of creation, though. Large-scale industrial structures can be built for comparatively less money, and job locations require fewer personnel. Since 3D printed buildings are made of components like concrete, plastic, raw soil, and organic waste from the rice production process, the procedure may also be more environmentally friendly than conventional building techniques.

House projects made with a 3D printer

The following are some of the most interesting projects of houses made with 3D printing techniques:

Live Construction

On a list of innovations, this home may be the most inventive—but no one resides there. This is due to the fact that this house was constructed at the International Builders Show on the convention floor. What better way to demonstrate the possibilities of 3D printing than to build a full house in front of business representatives? The advancement of technology is astounding.

This project also saw the debut of Black Buffalo’s own 3D printer for building materials, which the company claims can save labor expenses by 80% and material prices by 70%.

Habitat for Humanity

When Habitat for Humanity welcomed tenants into their first 3D-printed home in December of 2021, they gave the world a wonderful Christmas gift. Alquist and the humanitarian organization collaborated to print the one-story concrete house.

Further evidence of the technology’s enormous cost savings comes from the organization’s decision to give low-income families that volunteer with it the opportunity to live there. This initiative also serves as Alquist’s proof of concept for moving forward with their ambitious Virginia objectives.

The fact that this two-bedroom house was printed in under 12 hours may be the most astounding. The ability to build affordable homes in the same amount of time it takes to prepare overnight oats is something Habitat for Humanity expects to see more of in the future.

Casa Covina

The San Luis Valley’s Casa Covina was created as a design test. Three cylinder volumes or vaulted constructions are connected to create the structure.

The hut was designed with two people living together comfortably in mind, taking into account the coronavirus’s requirements for social isolation and withdrawal. Sand, silt, clay, and water are utilized to make the Casa Covina’s adobe walls. A three-axis Selective Compliance Articulated Robot Arm is used to print the structure.

The main attraction is an inflatable pink roof that may be set up in case of rain or snow. This outstanding illustration combines cutting-edge and antiquated technologies to produce lasting, livable solutions.

Curve appeal

A dynamic 3D-printed home called Curve Appeal was constructed using 3D-printed plastic, carbon-fiber panels, and glass walls. Compared to other 3D-printed homes throughout the world, this structure has very striking imagery because of its free-flowing forms and parametric facade. This 1,000 square foot home is designed by WATG. This construction is the first of its kind and was produced utilizing Branch Technology’s freeform method. The dynamic, curving facade is both aesthetically pleasing and optimally structurally sound.

Curve Appeal is truly futuristic due to its ground-breaking revolutionary construction methods and cutting-edge technologies like solar carving and passive mechanical systems.

PassivDome House

The PassivDom House is perhaps one of the most environmentally friendly and economically efficient 3D-printed homes. The entire home is built to utilise solar energy. In contrast, water is produced from the moisture in the air. This serves as an auxiliary amenity. PassivDom House is a prime example of futuristic home that was constructed in a Nevada factory utilizing a massive 3D printer.

The restroom is technologically advanced in order to clean and recycle water. The home is truly “Off-grid,” built to use as few resources as possible.

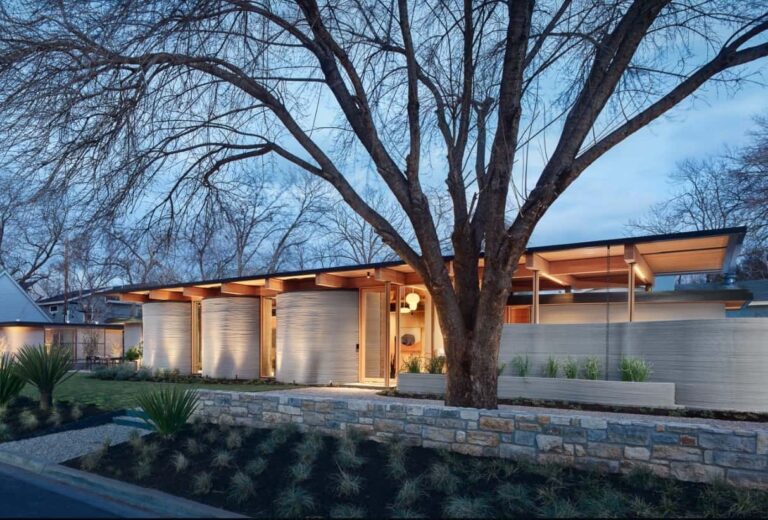

Houses made with a 3d printer always give high standard of comfort

The residences have a futuristic style that gives them an abandoned appearance, evoking the image of rocks in an oasis surrounded by trees.

The homes were constructed in a sustainable and energy-efficient manner, and they satisfy the highest standards of comfort.

Read also: 3D printing: all the benefits for sustainable production