The advancement of digital construction has paved the way for the Construction Industry in a dynamic fashion. Automation in construction is utilizing these digital systems to perform specific tasks during the construction process. AI in construction increases productivity and is not a threat to employment.

Automation tech is taking in the work that fills the positions and propels youth as the workforce matures and when the labour faces increasing labour scarcity.

The ascent of automation in construction is a trend that will only be important as the future arrives. It is transforming the industry and influencing the way people build infrastructure and cities. Here, artificial intelligence comes under the umbrella of automation in the construction industry.

As we proceeds, we will have a comprehensive understanding of the opportunities, challenges, and technologies that take place in this field, with automation playing its hand.

Table of Contents

Opportunities for automation in construction

Opportunities that lie in the realm of automated construction are overflowing. One might bump into many opportunities at a time. Let us explore them more comprehensively:

- Automation of traditional physical tasks on-site: Heavy machines like bulldozers, excavators and cranes, when included with automation, can considerably increase the effectiveness and decrease the risk of hazards. Sensors and GPS can be imbibed in these machineries to perform with accuracy. Automation systems, when fixed up with concrete mixing and pouring machines, can minimize waste and ensure the quality is good.

- Automation of modular construction in factories: This step involves the generation of components in the factories, etc. Organizations like Quantum Assembly are utilizing automation in construction to save costs, money, and time and decrease waste and overall environmental impact. Quality and consistency are also taken into account, with an increased priority to safety. The logistics part of the business can also be managed by automated systems where the transportation of modular materials from the factory can be moved to the site very efficiently.

- Comparison of automated projects with traditional build approaches: Before getting into the intricacies, while comparing, it is essential to note the investment costs, procurement of labour, technology and other aspects.

| Aspect | Automated Projects | Traditional Build Approaches |

| Duration | Efficient and speedy production time | Slower, less consistent production time |

| Adaptability | Less adaptable | More Adaptable |

| Safety factor | Upgraded safety | Increased risk |

| Process of construction | Flexible construction in factories | Field construction |

| Cost | Initial Investment: Higher | Initial Investment: Lower |

| Quality | Increased consistent standard | Quality may fluctuate |

Read more: The drone light shows trend is gaining pace and getting popular

Key technologies driving automation

By the year 2030, the construction industry is set to welcome a trio of state-of-the-art technologies: Artificial Intelligence, Machine Learning, Drones and Robotics, with an increased concentration towards 3D printing. In this context, these points are explained here as follows:

1. Robotics and drones

The demand for drones increases as technology advances. In the construction field, they can be used for tasks like monitoring, analyzing, measuring, inspecting and increasing the complete efficiency. Robotics can be utilized for handling construction work such as demolition, concrete pouring, etc.

2. Machine learning and artificial intelligence

By 2030, AI-induced algorithms will rule the scheduling, resource allocation and project planning process. When it comes to safety, AI-based systems will oversee and mitigate the safety risks and increase job site protection. AI-generated maintenance frameworks will stop equipment downtime by predicting issues before they result in disturbances.

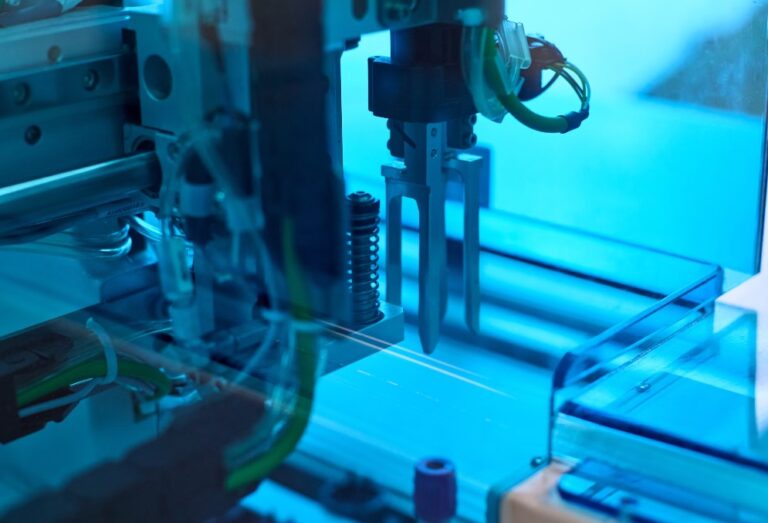

3. Advanced components and 3D printing

Carbon fibre-backed concrete 2020 will be deployed to increase the buildings’ structural rectitude, longevity and strength. The name of 3D printing also knows additive manufacturing. It is being utilized to generate sophisticated building materials with great accuracy and effectiveness. This piece of technology possesses the potential to reduce wastage, drive the construction of sustainable frameworks and minimize costs.

Challenges and considerations for implementing automation in construction

The execution of automation in construction brings forth challenges and considerations that need to be acknowledged and solved. As much as the advantages help improve the construction industry, it is important to be mindful of the challenges and obstacles to ensure a smooth transition in this realm.

- Safety and supervisory compliance: As the technology in automation advances, the protocols for safety and regulation have also been updated. It is important to note that these regulations;

- Unsuitable technologies: Imbibing numerous automation systems and technologies can be demanding, mainly when they are not manufactured to work in sync;

- Nature of the trade: The construction realm is often fluctuating, which can cast a challenging shadow for automation execution. Construction activities require flexibility for the dynamic conditions;

- Labour: Sophisticated automation technologies demand technicians and labour who are skilled enough to operate and handle them. That is why investment in the training of this workforce is important to fill the skills aspect.

The transformative potential for the future

The construction industry possesses the transforming potential of automation that can significantly alter and improve the industry’s aspects. It can increase productivity, efficiency, safety, etc, on a larger scale. That said, one must also acknowledge the challenges and draw up solutions to overcome them. Despite these obstacles, one must embrace these innovations to conquer competitiveness in this field.

Read more: Robotics development: 5 trends of the coming years